hardness test of metal specimen discussion|steel hardness testing methods : vendor © 2008-2024 ResearchGate GmbH. All rights reserved. Terms; Privacy; IP . WEBThe latest tweets from @eromecom

{plog:ftitle_list}

webAcompanhantes trans e travestis em São Paulo com local, disponíveis para sexo. Veja fotos e vídeos reais das acompanhantes em SP e mande mensagem agora mesmo!

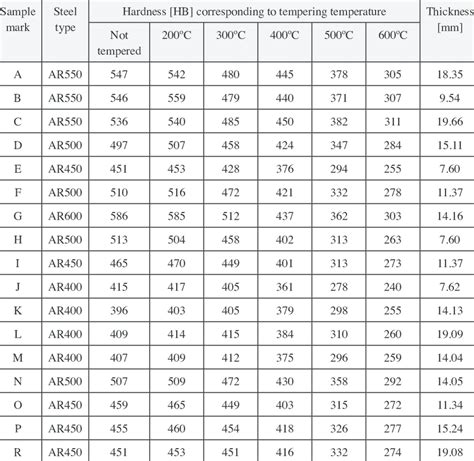

complex geometry of materials and their correlation between tensile strength and hardness, hardness testing is the best method to confirm the survival and performance of the specified. metal.complex geometry of materials and their correlation between tensile strength and .

© 2008-2024 ResearchGate GmbH. All rights reserved. Terms; Privacy; IP .The hardness test is performed to determine the suitability of a material for a given application. Rockwell hardness test is developed by the Wilson instrument co U.S in 1920. This test is an .

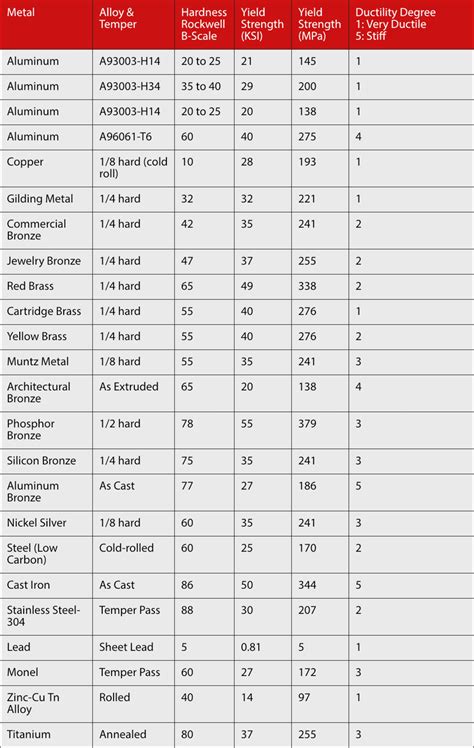

Hardness is resistance of a material to plastic indentation, scratching, surface penetration, or wear. These properties are all related to the resistance against plastic flow (permanent .Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .

Hardness Test Average 99.7 227.5 Conversion table value 95 220 Table . Hardness values for aluminum. 6061 Aluminum Rockwell B Test Brinell 10/500 Hardness Test Average 53.825 95.6 Conversion table value 54 87 Table . Hardness values for brass. Brass Rockwell B Test Brinell 10/500 Hardness Test Average 71.1 110.5Each hardness test method, or scale, is defined with a particular type of indenter, a specified . Repeat for different force in increment of 50 kgm up to 1000 gm for steel and 600 gm for aluminum. Sample Data Acquisition form: Dr. S. E. Beladi, PE Mechanics of Materials . Steel and Aluminum to vicker hardness value. DISCUSSION: 1. What are .

Table 5: Ranking 10 metal hardness Metal sample Copper Al alloy 6061 Brass Phosphor Bronze Al alloy 2024 Tool Steel Stainless Steel C1018 Steel Ductile Cast Iron Gray Cast Iron Hardness (RB) 62 67 72 79 81 90 91 91 95 100 The hardness test results was valid because the hardness measured values in 3 trials of each sample closely matched with .

Brinell Hardness Test- determination of hardness of steel and aluminum . Brinell hardness test was used in attempt to examine the relation of the deformation of metal specimen to the hardness property of a metal. . Gradient for steel curve 2250-1500 62.5 kg/mm2 36-24 Gradient for Aluminum 2250-1750 32-25 71.4kg/mm2 60 DISCUSSION OF THE .Specimens of various metals (aluminium, brass, copper, high speed steel in this experiment) Indenters Rockwell hardness testing machine (b)Theory There are many de nitions for hardness depending on the material. For metals, the most appropriate one would be ‘resistance to permanent deformation’. Hardness can be Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . To determine the Brinell hardness of a metal material, apply a certain load F with a spherical indenter of diameter D onto its surface and maintain it for a specific duration. . the ratio of F/D 2 is 30, 10 .Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).

When testing the hardness of metals, static forces are predominantly used, and the test load is slowly increased. . Conditional on the size of the main load applied to a specimen when conducting the hardness test, differentiation is made between micro, low-load, or macro hardness testing within ISO standards.

2019 how hard is ged test

steel hardness testing methods

7 Hardness test of metal specimen 8 Buckling Test of Slender Columns . North South University Department of Civil and Environmental Engineering CEE 212 SOLID MECHANICS LAB WORKBOOKS FOR LABORATORY PRACTICE EXPERIMENT NO: 01 . DISCUSSION: (Discuss on the results found, graphs, and failure patterns and also compare the results found .3.2 Conducting the Test. Positioning the Sample: Secure the material sample in the testing machine.; Selecting the Indenter: Choose the appropriate ball diameter based on the material hardness.; Applying the Load: Gradually apply the specified load using the machine.The load should be maintained for a predetermined dwell time, usually between 10 to 15 seconds.

created to see how well a metal’s hardness increases when quenched. This test has been “standardized” and uses a uniform size sample of different metals, heated and then quenched on one end. Afterwards, hardness tests are performed on the sample as a function of distance from the quenched end. 3. 12. Working Principle 1. SELECTING THE HEAD AND TEST BLOCK Hardened steel and hard alloys like Cast Iron were tested in the Rockwell C scale, using a diamond cone as head and a 150 kg major load. Brass was tested in B scale, using a 1/16” ball as head and a 100 kg major load. Copper was tested in F scale, using a 1/16” ball as head and 60 kg major load.Brinell Hardness Test; For Brinell hardness test. The hardness of materials are test by pressing a steel ball or tungsten carbide ball for a time of 10 to 15 seconds into the surface of specimen by a standard load F [kgf]. After that, the diameter of the indentation d [mm] is measured when the load is removed.

The Brinell hardness test is ideal for measuring the hardness of metals with coarse or inhomogeneous grain structures, such as cast iron and softer metals like aluminum alloys. It measures the diameter of a larger indentation, which averages out variations in the material’s microstructure, providing a more representative hardness value for .

The impact test determines the impact toughness, which is a material property of metals, most commonly by measuring the work required to fracture metallic specimen under impact. The impact toughness test of metals provides .TableofContents ListofFigures ix ListofTables xii 1.Introduction 1 2.RockwellHardnessTest 2 2.1Significanceofthetest 2 2.2Rockwellindentationtestprinciple 2 2 . Micro-hardness value decreased from 548 HV for as received 0.6% C steel to 256 HV for annealed sample and 412 HV for normalized sample. The more wear resistance of as received sample as compared .

Brinell Indentation Diagram. In the standard method of the Brinell Hardness Test, we use 250 to 500 kg of load for soft material and 500 to 3000 kg of load for hard material such as steel and iron.test procedure, hardness testing types, hardness testing machine, hardness of different metal specimens, failure patterns etc. 4. APPARATUS Rockwell Hardness Testing Machine 5. SPECIMEN Specimen of mild steel (MS), brass, cast iron, aluminum and high strength steel (HSS). 6. THEORY

- Specimen thickness should be 10 times higher than the depth of the indenter . and stainless steel etc. Figure 4. Hardness test equipment 4.1 Results . Discussion of your results and a conclusion. References ASM International, Hardness Testing, 2nd Edition, 06671G. .

Brinell hardness test is a hardness testing method that gives a measure of to the overall strength of a material. In this test generally constant loads are applied usually in the range 500–3000 N, for a specified period of time (10–30 s). In this test, a 5 or 10 mm diameter hardened steel or tungsten carbide ball is used as an indentor on the flat surface of a work piece.This document describes procedures for harness testing of metallic materials using the Rockwell scale. The Rockwell hardness test measures the indentation made by specific loads on a material's surface. There are different Rockwell scales that use varying loads and indenters depending on the material. The experiment uses a Rockwell hardness tester with a diamond .

sheet metal hardness chart

[14]. Methods have also been developed to test for hardness properties of steel without destroying the test specimen [15]. In general, advancements and innovation in hardness testing are abundant in academia. B. Finite Element Method load) causes an increase in .Additional CRMs near, or bounding, the hardness of the specimen(s) may be used during the procedure. 7 S. AMPLING . Whole components, or sections thereof, are typically presented to the indenter for hardness testing. Hardness readings should be interpreted to apply only to that material in the immediate vicinity of the indentation.Carbon steel| 38| 4. 5. 5 4. DISCUSSION The results of the Vicker’s hardness test on the mild steel and the carbon steel specimens give a higher Vicker’s hardness for the carbon steel specimen, as shown in Table 1a and Table 1b. . The results of the Rockwell Hardness test on the high carbon steel specimen and the ASSAB steel specimen give .

well as tension, hardness, torsion, and impact tests in particular. Mechanical Testing Mechanical tests (as opposed to physical, electrical, or other types of tests) often involves the deformation or breakage of samples of material (called test specimens or test pieces). Some common forms of test specimens and loading situations are shown in .

2021 training is the test hard

web4 de fev. de 2012 · A eletricidade define-se como a área da física que se ocupa dos estudo dos fenómenos eletrostáticos, eletrocinética e do eletromagnetismo. A eletrónica pode-se .

hardness test of metal specimen discussion|steel hardness testing methods